Unique Silicone Extrusion Applications in Architecture and Design

Silicone extrusions are commonplace in architecture and design. Learn more here.

Sales: +44 (0)1903 205532

Search our extensive catalogue of tools for common profiles. The largest collection online.

With over 8000 unique dies produced, our team has the skills and experience to meet your requirements.

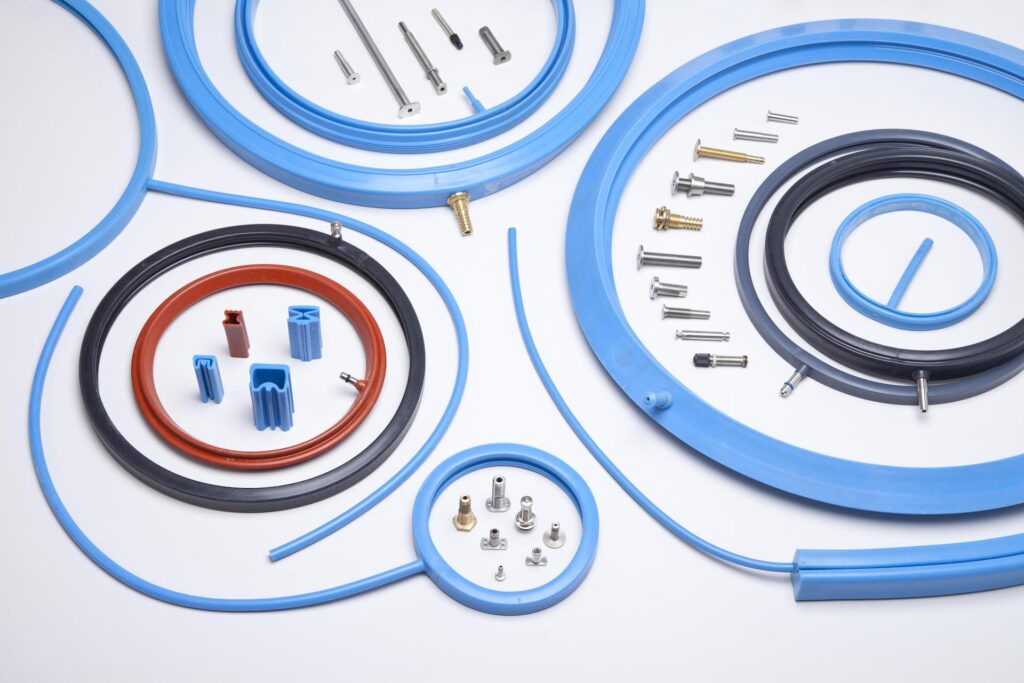

Custom made silicone rubber inflatable seals. Manufactured in-house, delivered in as little as 14 days.

We are able to manufacture a wide range of silicone rubber products using bespoke or existing tooling in quantities from small batches to large production orders.

We offer the highest quality inflatable seals, all manufactured and tested in-house. Our seals can be made using existing or bespoke tooling, moulded corners and a variety of valves and air connections.

Our inflatable seals brochure contains information on inflatable seal applications, available profiles, valves and moulded corners. For any additional information please contact our team of silicone engineers.

Over the last 30 years we are proud to have built a reputation based on exceptional customer service, flexibility and the ability to deliver challenging and innovative silicone products.

Our team are dedicated to ensuring parts are delivered on time and to specification. We have been ISO 9001 certified since 1998 and are currently working towards ISO 14001 and ISO 45001.

Silicone extrusions are commonplace in architecture and design. Learn more here.

You’ll encounter silicone everywhere. Here are just a few of the places you’ll find it.

Discover how silicone extrusions have transformed the medical industry.

© Viking Extrusions. All Rights Reserved.

Designed by Damteq.