Silicone is a synthetic polymer made from the chemical element silicon.

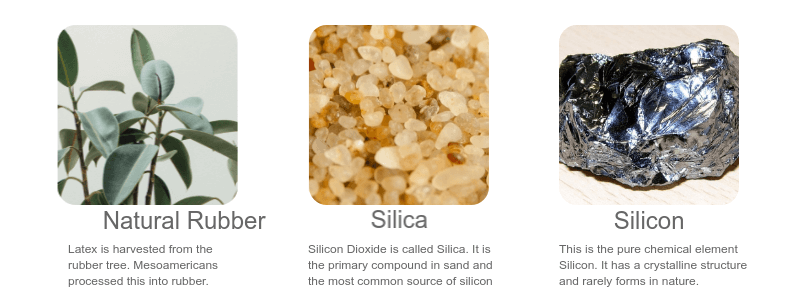

While very similar sounding, there is quite a big difference between silicon and silicone. Putting it simply, silicon is the raw chemical element and silicone is a rubber material that is primarily derived from silicon.

Silicon in its purest form is extremely brittle and hard. It forms as a crystalline solid with a unique grey/blue metallic sheen. It is actually the eighth most common element in the world. Despite this, it rarely forms as a solid in the earth’s crust. It is most commonly found as silica which is an oxide of silicon and also the main constituent of sand, where it is extracted from and passed through hydrocarbons.

While primarily derived from silicon, silicone also includes hydrogen, carbon and oxygen. It is a man-made material that has phenomenal viscoelasticity, meaning that is both viscous and elastic. Viscoelastic materials are generally referred to as rubbers.

Silicone rubber is categorised as a synthetic elastomer due to the fact that silicone polymer is both man-made and displays elastic properties. As compounds, silicones are also made up of repeating functional groups known as siloxanes. Siloxane is an alternating chain of silicone-oxygen atoms.

How Is Silicone Rubber Made?

To make silicone, the silicon atoms and the silicon dioxide compound silica must be isolated from each other. This process is done by heating a large quantity of quartz sand to incredibly high temperatures of up to 1800ºc.

There are several processes that follow this where the silicon is combined with the methyl chloride and heated. It is then distilled into a polymerized siloxane known as polydimethylsiloxane which can then be further polymerized.

At Viking Extrusions all our grades of silicone are mixed using our in-house milling facilities. We take the raw silicone compound, add pigments and additives as required then blend with a catalyst ready to be extruded and cured by High-Temperature Vulcanisation (HTV). The use of in-house facilities means everything we produce is fully traceable to its original batch. This way we can ensure the highest standard of quality management throughout the entire process from raw compound to finished product. As such, we produce large quantities of both food-grade silicone and medical-grade silicone.

What Are The Uses Of Silicone?

The production of silicone rubber-based compounds can be done on a mass scale at relatively low costs. For this very reason, silicone has become the go-to material for applications such as:

Sealants – Silicone is a brilliant material to use in sealants as it is a highly flexible material that retains its stability in extreme temperatures, both high and low. In addition to this, it is water, moisture, and chemical resistant.

Adhesives – Many of silicones’ special properties make it a brilliant and phenomenally resistant adhesive. All of its properties and in particular its elasticity remains unchanged at any temperature.

Lubricants – For decades, silicone fluids have been used as excellent lubricants for both polymers and rubbers. This is because they have very low coefficients of friction.

Extrusions – One of the main reasons that silicones are commonly used for extrusions is that it is an incredibly stable material that has excellent temperature resistance and extreme durability. These properties make it the perfect material for products such as gaskets, caulks and seals as the silicone material works phenomenally in a huge temperature range due to its heat-resistant properties.

It can also be used for a wide range of other things such as cookware, automotive parts, electrical insulation, medical applications, fillers, coatings, breast implants, personal care products and a whole lot more.

What Are The Advantages Of Silicone Rubber?

Silicone products are used across a diverse range of industries due to its many useful properties such as:

- Thermal Stability- Silicone can maintain its properties across a wide range of extreme temperatures, from as low as -70°C to + 200°C.

- Low chemical reactivity

- Resistant to UV and Ozone

- Repels water – useful for making watertight seals and gaskets, as well as non-stick products

- Low toxicity

- Electrical Insulation – silicone can be formulated to both be insulating and conductive.

- Does not support microbiological growth.

Learn More

To learn more about the properties and applications of silicone rubber please contact one of our technical advisors who will be happy to answer any queries.