Menu

Sales: +44 (0)1903 205532

Waterproof materials are the most important thing to consider when building houses or aeroplanes. It’s also essential to manufacture apparel and home appliances using a highly water-resistant material. The good news? Silicone rubber is one of the world’s most waterproof materials in different industries.

So what exactly is silicone rubber? Made from Silicon, Carbon, Hydrogen and Oxygen, this synthetic rubber has abundant properties that have made manufacturing much easier for many businesses. Whether it’s pharmaceutical, construction, aerospace or automotive industry, you can bet silicon rubber is being utilised daily.

Highly stable and generally non-reactive, silicone rubber seals, strips and gaskets can withstand extreme environments and temperatures. While natural rubber can tolerate heat up to 85 degrees Celcius, silicone rubber can take continuous heat up to 200 degrees Celcius.

With a blend of organic and inorganic properties, silicone extrusions offer a unique and reliable resistance to water, fire and heavy chemicals.

With silicone rubber’s stability and strength, it’s no wonder most builders use it during construction. Whether providing solutions to prevent vibrations and sound or to protect properties from heat, cold and water, this flexible elastomer can do it all.

So what exactly is water-resistant silicone rubber used for in construction?

Many products for sale require the super strong water-resistant properties of silicone rubber. Let’s explore some of the most popular silicone-based objects:

Shoes

Over the years, shoe designers and companies have added silicone rubber to soles instead of leather to prolong shoe life and keep feet dry and protected at all times. Silicone rubber is also fatigue resistant, meaning it can withstand repeated use’s wear and tear without compromising quality. In addition, apparel industries love silicone rubber due to its hypoallergenic and odourless qualities.

Cooking Equipment

Utensils, cookware and moulds would be useless if they were weak. Luckily, most food industries use silicone rubber in cooking equipment to protect against deterioration from liquids and extreme heat. Food-grade silicone rubber is also one of the most hygienic materials to use thanks to its non-porous properties, making them easy to clean and remove bacteria.

Medical Supplies

Water-resistant, hygienic and durable materials are crucial in the medical industry. Whether hearing aids, tubing, packaging, chemo cooling caps, surgical trays or face masks, silicone rubber offers a practical solution for most apparatuses.

Toys

Silicone rubber-based toys are a safer alternative to traditional plastic. This polymer is super flexible and can mould into any shape and colour. Plus, it’s highly durable and waterproof, making them perfect for bath toys.

Latex is also known as natural rubber. While rubber is produced naturally from the sap of rubber plants, silicone also contains natural latex blended with synthetic additions to enhance its properties.

There are a few similarities between latex and silicone rubber, including low-temperature tolerance. However, there are significant differences, such as:

Silicone rubber is ultra-dynamic, lending itself to many of our core industries like aviation, electrical and medical sectors. As a material, silicone is super strong and flexible, offering an easier way to create products and industrial parts.

Silicone is a synthetic elastomer. This means it has sufficient elastic properties that can be used for various products such as extrusions.

As a material, silicone comprises silicon, oxygen, carbon and hydrogen. Be careful not to confuse silicon and silicone – they are entirely different. One comes from a natural element, and the other is a manufactured material.

While silicone is a popular material, it’s a complex production process to manufacture. This is one of the reasons why silicone is more expensive than regular, natural rubber.

This unique material is a favourite among most industries for extra durability, making it both high-quality and cost-effective.

As one of the most synthetic rubbers on the market, silicone has been a game-changer for even the most demanding industries.

Let’s get started on why you should choose silicone rubber for your business.

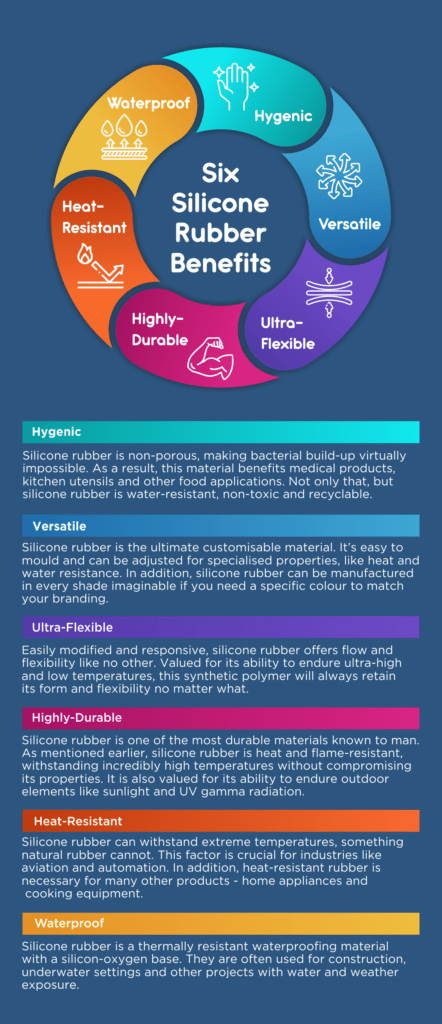

Silicone rubber can withstand extreme temperatures, something natural rubber cannot. This factor is crucial for industries like aviation and automation. In addition, heat-resistant rubber is necessary for many other products – home appliances and cooking equipment. In fact, most compounds can stay wholly intact and generally retain their properties in extreme temperatures. Silicone rubber can also maintain flexibility in much colder temperatures, making it the perfect all-rounder for use globally.

Silicone rubber is non-porous, making bacterial build-up virtually impossible. As a result, this material benefits medical products, kitchen utensils and other food applications. Not only that, but silicone rubber is water-resistant, non-toxic and recyclable.

Silicone rubber is the ultimate customisable material. It’s easy to mould and can be adjusted for specialised properties, like heat and water resistance. In addition, silicone rubber can be manufactured in every shade imaginable if you need a specific colour to match your branding.

Using silicone rubber outdoors is an excellent choice. This weather-resistant material can withstand prolonged amounts of sunlight, UV light, radiation, harsh temperatures and storms. Silicone sealant is one of the most popular ways to use silicone outdoors.

Because silicone rubber compounds are made from a mixture of silicone and oxygen atoms, it offers a remarkable resilience that most materials don’t possess. In fact, silicone rubber is chemically inert and can endure many substances, such as acids and water.

Easily modified and responsive, silicone rubber offers flow and flexibility like no other. Valued for its ability to endure ultra-high and low temperatures, this synthetic polymer will always retain its form and flexibility no matter what. Plus, it boasts an impressive compression set, maintaining its shape and flexibility despite

Is silicone rubber durable? Yes, silicone rubber is one of the most durable materials known to man. As mentioned earlier, silicone rubber is heat and flame-resistant, withstanding incredibly high temperatures without compromising its properties. It is also valued for its ability to endure outdoor elements like sunlight and UV gamma radiation.

As you can see, choosing silicone rubber is a no-brainer. Explore Viking Extrusions to learn more about this remarkable material and see how we can help your business.

Silicone extrusions offer a solution to many challenges faced by construction workers. For example, unintentional movement, leaks and incompatible products can be a nightmare on building sites, but with silicone extrusions, these problems are easily managed, making work more streamlined.

In fact, these days, construction relies heavily on high-quality silicone extrusions for various projects. So read on to find out some of the purposes of using silicone extrusions in construction.

Silicone extrusions are manufactured sheets of silicone. They are thin and flexible and can be made into any shape, length or colour. Thanks to its weather, water and heat-resistant properties, silicone is the leading material of choice for most civil engineering projects.

Choosing the right silicone extrusion for specific applications within the construction process is vital. Explore Viking Extrusions to find out what we can do for you and your business today.

There is a lot of confusion around addition cure silicone, mainly because there are different types and categories to do with it.

In this guide, we will answer all of the common questions about addition cure silicone rubber that we often hear about.

Addition cure silicone is another name for silicone that is catalysed or ‘cured’ with platinum. The word ‘addition’ refers to the curing system involved in this process that involves a mixture of a silicone polymer and a catalyst with the additional presence of platinum.

Condensation cure silicone is another name for silicone that is catalysed or ‘cured’ with tin salts.

The main difference is chemical, referring mainly to the type of metal used to catalyse or cure the base rubber. In this case platinum is used for addition cure silicone and tin salt is used for condensation cure silicone.

Both platinum (addition) cure silicone and tin salt (condensation) can be cured at room temperature. This similarity is often why they are often mixed up. But they are actually very different from each other, and they aren’t compatible with one another either.

No one chemistry type is superior over the other. Rather, each type has unique properties that give them the edge over the other type in certain situations. Here are the main differences between the two:

| Addition (platinum) cure | Condensation (tin salt) cure |

| Offer exceptional heat resistance and the ability to work under higher temperatures | Considerably cheaper to make |

| Very pliable and tough | Biodegradable |

| Can split or tear if stretched or twisted too much | More tear-resistant |

| The curing process is trickier and requires more careful skill and accurate mixing | Tend to weaken after 1-2 years if they are overused |

| Food safe, skin safe and transparent versions available | Preferred for general mould making — can capture very find & intricate details |

| Virtually no shrinkage in the cure process | Shrinks slightly during cure process |

| Incompatible to some chemicals including: nitrogen, sulphur, sulphur vulcanised rubbers, phosphorous and condensation cure rubbers | Works great with plaster casting, polyester, epoxy, gypsum, wax and resin |

While we’re on the subject of differences, you might also be interested in our guide on understanding the difference between peroxide and platinum-cured silicone here.

Addition cure silicone is popular because it is very flexible yet durable, both water and fire resistant, and excellent for making moulds or casts.

It is also remarkably versatile. For example, it can be combined with lots of different types of resins and materials. For example concrete, brick, fibre glass filled resin, polyester, stone, acrylic resin — and even another type of addition cure silicone.

Other great properties of addition cure silicone mould making rubber include:

Good to know:

Addition cure silicones do not produce by-products during the curing (cross-linking) process. All of the chemical reactions are contained internally. This makes them perfect for moulds or component parts that are manufactured in a sealed environment.

And because they are so durable and resistant to the elements (heat and humidity) they are ideal for moulds that often need to be stored away for long periods of time.

Addition cure silicone is very popular across many industries. Including:

Addition cure silicone is particularly good for resin and plaster casting.

| Addition (platinum) cure | Condensation (tin salt) cure | |

| Inhibition | Critically sensitive to sulphur and will fail to cure when exposed. | May still cure over models containing sulphur if the model surface is sealed with an acrylic spray. |

| Shrinkage | Generally stable and resistant to shrinkage. | Exhibits higher shrinkage over time, though how extreme this is will be determined by many variables, including mould configuration, etc. |

| Library life | A long library life, lasting even for decades. | Library life can be as little as 12 months (which is fine if you have a short term project) or as long as 5 years — it depends on what type of tin-cure silicone you go with. At the end of its library life, the mould will tear easily and be unusable. |

| Production life | Impossible to say — it depends on the application and a lot of other different variables. | Impossible to say — it depends on the application and a lot of other different variables. |

Warning:

Some chemical compounds can contaminate and inhibit the cure process, preventing the necessary cross-linking from taking place.Keep your addition cure silicone rubber away from the following materials: latex and rubber gloves, masking tape, amine, PVC stabilisers and epoxy resin catalysts. You also cannot let addition cure silicone come into contact with condensation cure (tin-catalysed) silicone, or any sulphur containing material either.

At Viking Extrusions, we specialise in addition cured silicone — or platinum-cured silicone profiles as we like to call them.

We love working with platinum-cured silicone for all of the reasons described above, but also because it has excellent biocompatibility and is FDA and USP Class VI approved — making it suitable for medical and pharmaceutical applications.

Over the last 30 years, Viking Extrusions are proud to have built a reputation based on exceptional customer service, fast lead times and the ability to extrude innovative and complex silicone products. We pride ourselves on our customer service, fast lead times, and ability to extrude complex probiles.

We have been serving worldwide customers for over 30 years now with profiles and components that are both complex and diverse. We pride ourselves on the knowledge and expertise that is available in-house, accumulated through years of prototyping and development work.

Years of continued investment have resulted in the company owning an impressive range of plant and equipment that is both high tech and ultra-reliable. Now we have over 8000 stock dies for profiles, cords and tubes — ensuring that most requirements can be catered for without a tooling charge.

If you’re interested or just have a question about our services, contact us today. You can email us or telephone — we’re always happy to help.

We are often asked, what’s the difference between silicone curing and vulcanisation? In truth both terms describe essentially the same process — the transformation of the polymer into a cross-linked rubber.

But of course there are shades of difference. No two words mean precisely the same thing. And so in this article we are going to delve deeper into just what distinguishes both the curing and vulcanisation process, and explore a little bit more about the properties and applications of both types of silicone rubber in the world today.

The rubber curing and vulcanisation process is identical, but it’s the way that this process is carried out that distinguishes the two from each other.

Vulcanisation is the name we give to curing when sulphur is used in the process. Mineral sulphur is commonly used to help form cross-links between the rubber chains because it helps to elongate the properties of the rubber — making it more elastic in the process while at the same time making it more stable and rigid (source).

There are many other ways to cure silicone rubber without sulphur. Including:

These different curing mechanisms all result in the silicone having slightly different properties suitable for different applications.

Did you know?

The word ‘vulcanisation’ is derived from the Roman god Vulcan, the god of fire and forge.

Silicone rubber is available in both solid and liquid forms. Both have similar structures, but require different methods of curing and processing.

Solid silicone is also sometimes known as high consistency rubber (HCR). It is manufactured in large batches, and the components are mixed at high temperatures following the injection of a peroxide catalyst. The cross-linking following the chemical reaction is only allowed to partially vulcanise. The end result is large sheets of partially cross-linked silicone ready for shipping.

Liquid silicone rubber (LSR) is a system featuring two components that also includes a platinum catalyst, a cross-linking agent, methylhydrogensiloxane and an alcohol inhibitor. It is normally processed using cold runner injecting moulding equipment, during which exothermic chemical reactions create long, stable chains of chemical bonds — resulting in a three-dimensional matrix. This method also serves to enhance the mechanical properties of the silicone (source).

When silicone rubber is cured or vulcanised, it tends to shrink but still keep its shape. It also hardens, meaning it is less likely to deform under stress. Furthermore, this hardening increases the tensile strength of the silicone.

Other great benefits of rubber curing or vulcanised silicone rubber includes:

Because of all these handy features, cured and vulcanised silicone can be found anywhere and everywhere, in applications all around us. Examples include:

And that’s just the tip of the iceberg. You will find cured and vulcanised silicone rubber is extremely popular across all major industries in production.

Across the extrusions industry, there are different types of cured and vulcanised rubber and silicone such as peroxide and platinum cure.

At Viking Extrusions, we specialise in two types of cured silicone rubber: platinum cured and peroxide cured.

We find there are numerous benefits to focusing on these two types.

For example, platinum cured silicone has excellent biocompatibility, and is FDA and USP Class VI approved — making it very suitable for medical and pharmaceutical applications. It also has a high tear-strength and is naturally transparent. This makes it highly suitable for food processing, peristaltic pumps and many other applications.

With peroxide cured silicone, peroxide is broken down by high temperatures which cross-link the polymers in the chain.

Peroxide silicone products have a long shelf life, an improved compression set performance, and are cheaper to produce than platinum silicone. The process of curing is also easier, and can be done at lower temperatures. The result is that peroxide cured silicone can be produced at very competitive prices.

Of course, each type has its own pros and cons. Find out more in our blog post ‘What are the Differences Between Platinum and Peroxide Cured Silicone?’ here.

The reason we stick solely with platinum and peroxide-cured silicone is because we find that it boasts a longer shelf life over the other types available, and is often cheaper to produce than platinum silicone.

Over the last 30 years, Viking Extrusions are proud to have built a reputation based on exceptional customer service, flexibility and the ability to deliver challenging and innovative silicone products. We offer fast lead times, exceptional customer service, and complex extrusions.

We have been serving worldwide customers for over 30 years now with profiles and components that are both complex and diverse. We pride ourselves on the knowledge and expertise that is available in-house, accumulated through years of prototyping and development work.

Years of continued investment have resulted in the company owning an impressive range of plant and equipment that is both high tech and ultra-reliable. Now we have over 8000 stock dies for profiles, cords and tubes — ensuring that most requirements can be catered for without a tooling charge.

If you’re interested or just have a question about our services, contact us today. You can email us or telephone — we’re always happy to help.

Silicone rubber is one of the most popular extrusion materials on the market. It is the go-to choice for a huge number of industries and applications. Silicone is a synthetic polymer that is made from the chemical element of silicon. Silicon sounds similar to silicone, however, they are two separate entities. Silicon is a raw chemical element and silicone is a rubber material, the link between the two is that silicone rubber is made up of mostly silicon as well as hydrogen, oxygen and carbon.

The process of extrusion is where a material, in this case, silicone rubber, goes through plastic deformation through the application of force which causes the material to flow through an orifice or even die (circular steel disks containing openings to create a profile). During the process the material adopts the dies cross-sectional profile, if the material has suitable properties then the shape will be retained at the end of the final extrusion. It helps to create an excellent finish to the material and also gives phenomenal freedom of form in the design process.

Here at Viking Extrusions, we have been providing the highest quality silicone rubber extrusions to a huge number of industries for over 30 years.

Silicone rubber is one of the most popular extrusion materials, and it is for good reason. The material has a long list of extremely great benefits that help to make it the go-to material for a huge number of different industries and applications. These advantages include:

One of the most impressive advantages of silicone rubber is its ability to withstand and perform phenomenally in extreme temperatures, both high and low. The material can withstand temperatures up to 305°c and as low as -70°c. The performance range from hot to cold is extremely impressive and can only be found with silicone rubbers.

With silicone rubber commonly being used in both the medical and food industries, it is extremely important to have good sterilisation. Silicone rubber has a non-porous nature which means that it will not be susceptible to a build-up of bacteria like E.coli and MRSA. The material is FDA-approved, meaning that it can be used in both the food and medical industries.

There are a number of reasons why silicone rubber can be used in far more applications than regular general-purpose silicone. One of the main reasons is that the material was made to have far better elongation and tensile strength than the general purpose grades meaning that it is more resistant to abrasion and fatigue.

Due to the material’s long list of benefits, it can be used in a number of different industries and applications. Its ability to work in all kinds of extreme temperatures means that it can be used in pretty much any environment and perform incredibly well. Many other materials will underperform when met with different temperatures and environments.

Due to all of the silicone rubbers’ incredible advantages, it is the go-to material for a huge number of different industries. There are a few industries that more commonly use silicone rubber extrusions. The industries that most commonly use the material are:

Silicone rubber is hugely popular in the food industry, for a number of reasons. Gaskets and other machine parts that come into contact with any food or drink are normally silicone rubber. This is because it is a non-reactive material meaning that it is phenomenal at stopping food contamination. In addition to this, silicone is also a reusable plastic which is far better for the environment than other single-use plastics.

Silicone rubber is also FDA-approved. This means that the material has been through extensive testing to ensure that it is safer for use in industries where contamination of material could pose severe health risks to the public.

The medical industry is another industry that often goes to silicone rubber as its number one choice for different applications. With medical applications, it is super important that the material used is safe. That is why the FDA-approved silicone rubber is so popular in the industry. Silicone has a non-porous nature which means that it will not be susceptible to bacteria build-up making it perfect for an industry where health is paramount.

Silicone is also high flexibility and tear resistant, making it perfect for transporting liquids and contains no plasticisers that could potentially contaminate a drug and create toxicological issues.

The last industry that commonly uses rubber extrusions is the automotive industry. Viking Extrusions started out 25 years ago providing rubber door seals to the automotive industry. Silicone is so popular in the automotive industry because of its immense reliability in both extremely high and extremely low temperatures.

In addition to this, the material is also resistant to weathering, UV, ozone, salt and a huge number of chemicals making it perfect for use in automobiles. These qualities make it the perfect choice for applications such as rubber seals, car door seals, windscreen rubber seals, and other seals found in cars.

Extrusion is a process where the material goes through plastic deformation through the application of force causing the material to flow through an orifice or even a die which is a circular steel disk which contains openings that can create a profile. During the extrusion process the material, in this case, silicone rubber will adopt the cross-section of the die. The extrusion process helps to create an excellent finish to the material and also gives freedom of form in the eventual design process.

Silicone rubber is one of the most popular material choices for a huge number of industries when it comes to extrusions. Fire safety is among the industries where silicone rubber seems to be the go-to, and this is for a number of reasons. Standardised silicone has many benefits that can help with fire safety, however, there are two main types of silicone that are used when thinking about fire safety.

There are actually two different types of extrusions that are used for fire safety. Heat-resistant silicone extrusions and flame retardant silicone extrusion are often confused with each other, however, they both have completely different properties.

Heat-resistant silicone is one of the two types of silicone extrusions that are predominantly used for fire safety. This is because it is manufactured to function properly and maintain its mechanical properties when met with extreme temperatures, both hot and cold.

The rubber material can withstand heat up to 305°c all the way down to -70°c, which is a far greater range than any other polymerised rubber material. Its ability to withstand such incredible temperatures allows the material of the structure to maintain its properties when met with any temperatures meaning that it can perform at its best in any environment.

A good example of a heat-resistant silicone extrusion would be a silicone seal used on an oven. This is constantly exposed to extreme heat but can still perform extremely effectively due to its incredible temperature range.

As you would expect from the name, flame retardant silicone extrusions are also commonly used in fire safety. Flame retardant silicone is so effective as it has been specifically formulated to have the ability to be self-extinguishing, something that no other material has. For a material to be classified as flame retardant it must go through stringent testing and must be subjected to a flame for a specified period to prove that it can perform correctly even when met with flames.

This silicone rubber also has low smoke and low toxicity. Therefore, in the event of a fire, they will not emit much smoke or toxic fumes. This is actually a very important safety standard in many industries that commonly use silicone rubber extrusions.

However, flame retardant silicones do not have the ability to withstand such impressive heat ranges as heat-resistant silicone extrusions. These can only withstand temperatures of up to 200°c. This is still impressive when compared with other rubber materials.

There are multiple silicone grades that meet flame retardant requirements for different industries. These include:

VFR(2) – This is a flame retardant grade of silicone developed for rail applications. It is available in 68° Shore A.

VFR 203-803 – This flame-retardant grade of material is specified for use in aerospace applications and is available from 20° shore A to 80° shore A.

EN45545-2 – This particular garde is standard in the railway industry and across other mass transit vehicles.

In certain industries’ working environments there are always potential dangers, with fires being one of them. When dealing with applications that go through extreme temperatures or things like sparks that could be a fire hazard, silicone rubber is undoubtedly one of the best materials for thighs such as extrusions to be made from.

Silicone is an extremely effective and safe material, which is why it is extremely effective to have silicone rubber extrusions bridging the components together in moving parts and machinery that could potentially be susceptible to fire hazards. The material also has the unique ability to help stop the spread of things such as toxic gas, smoke and fire that could pose a serious threat to workers.