Menu

Sales: +44 (0)1903 205532

Sales: +44 (0)1903 205532

At Viking Extrusions, we have worked tirelessly to remain at the forefront of the rubber extrusion industry, investing heavily in our team, equipment and facilities, ensuring we continue to produce industry-leading products that utilise the latest technology and innovative solutions.

As a leading custom silicone manufacturer in the UK and Europe, we are specialists in the design, production, and distribution of bespoke silicone extrusions, holding quality and customer experience at the core of our operations, with a proven track record spanning over 30 years of helping thousands of organisations, spanning across multiple industries and sectors.

In this article, we discuss how we have helped to transform the silicone rubber industry, our extensive capabilities, and why we have become the go-to destination for all aspects of rubber extrusion and moulding operations in the country.

As mentioned, we are the leading manufacturer of bespoke silicone extrusions and parts in the UK, backed by our team of experienced, qualified, and skilled experts with a dedication to continuously improving, adapting, and implementing the latest technology and production techniques.

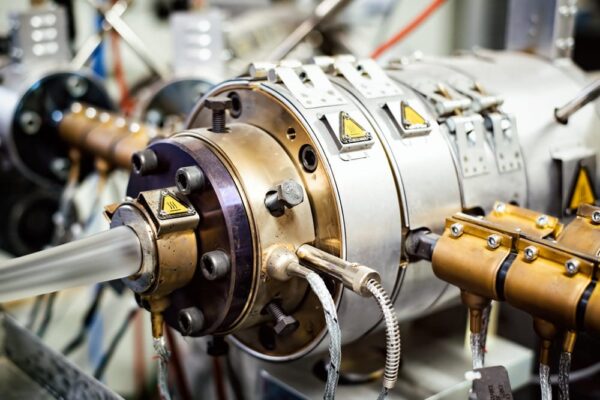

To ensure we continue to remain ahead of our competition, we have consistently invested in our equipment and facilities, with our Worthing-based headquarters housing an impressive range of plant and equipment, ensuring high quality and reliability. We have over 9000 stock dies for profiles, cords, and tubes, allowing us to cater for many requirements without a tooling charge.

The expertise of the Viking Extrusions team, combined with our outstanding facilities and equipment, means that we have extensive rubber extrusion capabilities, providing solutions and opportunities that aren’t available anywhere else in the industry. We are specialists in short runs and prototype work, meaning we have the perfect solution no matter how small your requirements are.

Additionally, as a leading custom silicone manufacturer, we can design and construct complicated moulds, which we can then produce on a large-scale basis, allowing us to meet customer demands and tight deadlines.

When choosing to work with Viking Extrusions, you will gain access to over 30 years of experience in the rubber extrusion industry, with our close-knit and knowledgeable team on hand to solve any issues, requirements, and queries, regardless of how complicated or simple they may be.

We have worked on and assisted thousands of projects across the globe, working within multiple industries and sectors to create custom solutions for our clients, ensuring specific needs are met and expectations are surpassed. We pride ourselves on the extensive skills and knowledge that we have available in-house, amassed through years of prototyping and development work, with profiles and components that are versatile, diverse, and high quality.

When manufacturing our silicone extrusions and rubber parts, we undergo rigorous checks to ensure we produce the high-quality and reliable products we have become known for. We have worked alongside our governing bodies to ensure we comply with all industry regulations and standards, with safety at the core of everything we do, especially when introducing new products, solutions, and manufacturing techniques.

Our latest innovation is the introduction of environmentally friendly VGPECO silicone, which has allowed us to continue to push industry boundaries, working towards ensuring a greener and eco-friendly future. Read our recent article about our latest environmentally friendly VGPECO products and how we are revolutionising the rubber extrusion industry.

Our custom silicone manufacturing capabilities aren’t the only factor that separates us from the competition, with our attention to detail and dedication to delivering a premium customer experience also putting us ahead of the pack.

Our dedication to care and close attention to detail has meant that as well as new business, we see a lot of repeat customers with no level of service, quality of product, and experience available elsewhere.

The thorough checks, controls, and elite manufacturing process we have in place can give you the confidence that you are receiving the best quality of product and service on the market. Throughout our history, we have developed strong relationships and lasting connections with our customers and partners, allowing us to provide trusted and cost-effective solutions.

We have also implemented an efficient and rapid delivery system to ensure we have unbelievably fast delivery times, enabling you to stick to tight deadlines, ensuring your project remains on track, and our reputation as the leading custom silicone manufacturer in the business remains intact.

For more information on our bespoke silicone extrusions or to discuss your project, contact our helpful and friendly team today, who are on hand to discuss your requirements and construct the perfect solution for your needs.

As the leading rubber extrusion manufacturer and supplier in the UK, we continuously push industry boundaries to introduce innovative and revolutionary products. One goal we are always striving to work towards is ensuring a greener and more eco-friendly future, showcased in our newest product offering, VGPECO.

In this article, we go into more detail about VGPECO, our newest and most innovative offering, providing an environmentally-friendly silicone solution.

This new product offers the same uses and benefits as traditional silicone products, working alongside multiple surfaces, including plastics, metals, and glass. However, VGPECO provides a greener alternative, utilising sustainable energy sources and manufacturing techniques that are less energy-intensive compared to the standard industry methods.

As a leading provider of premium silicone products, we can assure you that we only work with the best partners and provide the best materials and products to our customers. As our latest offering, you can be confident that when looking at our more eco-friendly products, you will receive the same high quality and durability as the rest of our ranges.

For more information on VGPECO, do not hesitate to contact our helpful and friendly team today.

The VGPECO manufacturing process works to reduce the amount of fossil resources used to create the silicone product, balancing the raw fossil materials used and offsetting these with bio-methanol.

The bio-methanol used within this process is created from sustainable and renewable plant-based sources, including grass clippings, hay or more. Additionally, all materials and resources used in the manufacturing process are completely traceable to the exact detail, meaning you can have complete clarity on the product you are using.

As mentioned, VGPECO provides the same guaranteed quality we have become known for and can be used for the same applications as our other silicone rubber products, ensuring it is suitable for various industries, including construction, food and dairy, pharmaceutical, and more.

Silicone is used in a diverse range of industries and is involved in manufacturing many everyday products you may not have given a second thought. For more information on the applications of silicone rubber and to explore the surprising industries that use silicone, read our recent article.

Traditional silicones have a larger environmental footprint than you may have initially thought due to the non-sustainable hydrocarbons used within their production and the energy-intensive process used to create these products.

Let’s work together towards a greener future with this revolutionary and sustainable silicone solution that maintains the same amazing properties as regular silicone products, including:

As well as selecting a premium quality of product, like our new environmentally friendly silicone solutions, it’s important to choose a trusted and reliable supplier, like Viking Extrusions.

At Viking, we have become renowned for our industry-leading quality and guaranteed reliability, having helped hundreds of customers and industry projects across the UK with our diverse range of silicone products, including inflatable seals, silicone rubber tubing, and many more types of rubber extrusions. When working with us, you will benefit from guaranteed quality control, bespoke extrusion-making capabilities, and industry-leading delivery times that you can rely on.

Explore our range of products online now or contact our team today for more information on our specialist capabilities.

Silicone rubber extrusions are a vital component of products and industries across the globe, used within everyday life, complex projects, and much more. To fully understand the importance of silicone extrusions and working with a trusted and reliable supplier, it’s vital to understand the manufacturing process and how this can affect the quality of the product you receive.

This article covers all the factors surrounding our silicone rubber extrusion manufacturing process, including the common uses of silicone extrusions and the importance of working with a leading manufacturer.

Continue reading to explore more about the manufacturing process we have adopted here at Viking Extrusions and how we work tirelessly to ensure guaranteed quality.

Silicone rubber extrusion is the process of creating parts with a continuous cross-sectional shape from uncured silicone rubber compound – this is done by pushing the material through a die to form the shape and then curing it with hot air.

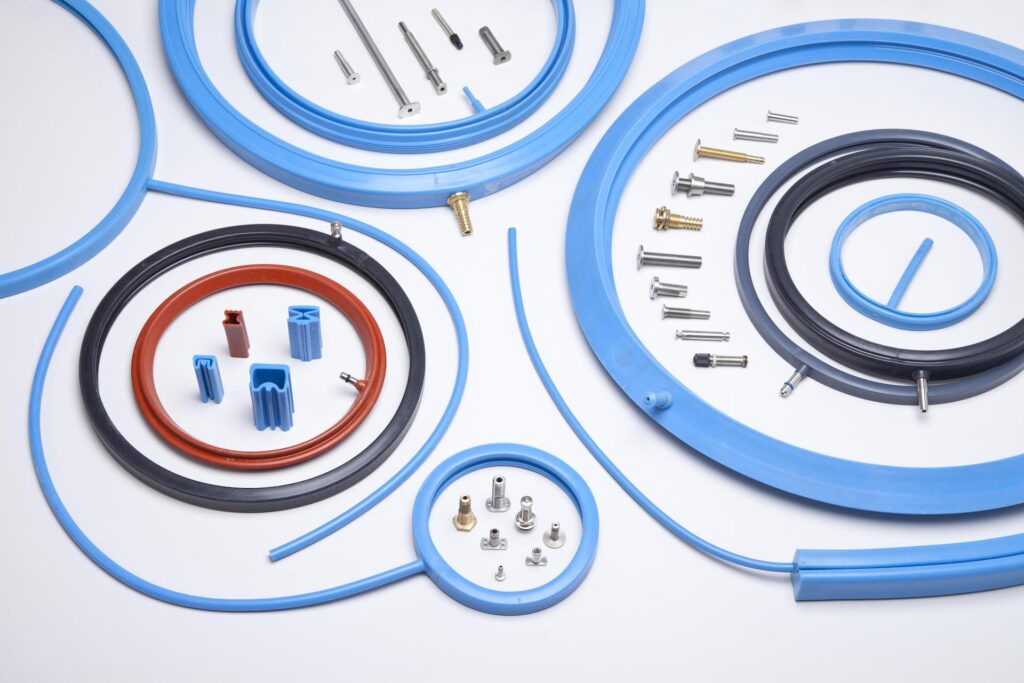

The types of products created by rubber extrusion include rubber profiles, tubing, strips, cords, and much more. There are numerous benefits and uses of rubber extrusions, stretching across multiple industries, some of which we will discuss in this article.

As mentioned, silicone extrusions are used in a wide range of applications around the world, with silicone rubber being the material of choice for many industries, providing numerous benefits and advantages.

Some of the industries that use silicone rubber the most include the:

These are just a handful of industries that use rubber extrusions every day.

Some of the most common applications for rubber extrusions include oven seals and baking mats due to their heat-resistant qualities, transition seals to effectively seal construction materials together, and car gaskets to reduce the frequency of replacements.

When manufacturing our silicone rubber extrusions, we undergo thorough and strict checks to ensure the top quality and reliability we are known for. We have worked tirelessly to ensure we have as efficient a process as possible, complying with all industry regulations and standards, with safety and reputation at the forefront of everything we do.

Below, we have outlined our manufacturing process and why this makes us the go-to destination for rubber extrusions in the UK:

Step 1 – Milling

The silicone compound is mixed in an open mill with the catalyst, pigment and any additives required to give it the desired performance characteristics.

Step 2 – Extrusion

The silicone is fed through a die to form the required shape using an extruder. The shaped material then passes on a conveyor belt through a hot air oven to cure the material. During this stage, regular checks are made to ensure the dimensional accuracy of the being made.

Step 3 – Post Curing

After extrusion, the cured parts are then post-cured in an oven for 8 hours at 200°C.

Step 4 – QA

All items are subject to a final round of QA, where the materials, colours and dimensions are checked before being signed off.

Step 5 – Packing and Dispatch

Items are then packaged – ready to be sent to the customer.

This process has allowed us to become one of the leading rubber extrusion manufacturers and suppliers in the UK, dealing with hundreds of customers across the country, spanning a wide range of industries and sectors.

For more information on our products and services or to order with Viking Extrusions, contact our helpful and friendly team today.

There are multiple benefits to using silicone rubber extrusions due to its long-lasting durability and flexible qualities, which makes it the perfect solution for various products and industries. Typically used for noise control, sealings and protection – the top benefits of using silicone extrusions include:

As you can see above, silicone rubber is an extremely versatile and dynamic material, which makes it the perfect option for numerous applications.

Working with a trusted and reliable supplier is imperative to the durability, reliability, and overall success of your project or service. As with any business or personal process, it’s vital to complete thorough research to ensure you choose an experienced supplier like Viking Extrusions, giving you complete confidence in the quality of products you receive.

Now that we have gone through our silicone rubber extrusion manufacturing process and the industry regulations we follow, you hopefully have a better understanding of what sets us apart from other suppliers.

The extensive checks, quality control, and experience of our team ensure guaranteed quality every time, giving you the confidence that you are receiving an industry-leading product at a competitive price and quick delivery times. Holding over 30 years of experience in manufacturing and supplying high-quality extrusions and rubber parts, we have developed a thorough and detailed manufacturing process that sets us apart from any other option on the market.

Another factor that puts us ahead of the competition is our unbelievably fast delivery times, allowing you to stick to your deadlines. We have a wide selection of rubber extrusions available to purchase today, including:

For more information on our silicone rubber extrusions and parts or to request an order today, contact our team, who are on hand to meet your needs and suggest the best solution.

The fascinating world of architecture and design features the use of unique materials and innovative techniques that continue to push the boundaries of what is possible. Among these is silicone extrusion, a versatile and robust material forging its place in the world of design. Silicone extrusions offer designers and architects numerous benefits, whether they’re creating unique design features or enhancing the functionality of buildings. Need silicone extrusions for your civil engineering project? See how Viking Extrusions can help.

It’s an incredibly innovative time to navigate the landscape of civil engineering. The industry is making some incredible breakthroughs. We now have the ability to mould this robust, versatile material into a vast array of shapes and sizes. It provides immense opportunities for architects, designers and manufacturers.

Silicone has a number of uses, and we explore this unconventional design element, explore its role in architecture and design and discover some remarkable silicone extrusion applications worldwide that demonstrate how they enhance aesthetics, functionality and durability in residential and commercial properties.

Silicone extrusions are crucial in modern architecture due to their inherent durability, resilience and flexibility. By tailoring them to specific design requirements, you can mould these extrusions into an array of forms and sizes to fulfil structural and aesthetic requirements. They serve as sealing gaskets for glazed façades, which reduces air and water penetration and subsequently enhances energy efficiency. Moreover, the industry uses silicone extrusions when creating dynamic façade systems. You can find them in the intricate detailing of architectural masterpieces.

One unique application of silicone extrusions in architecture is in the construction of the London Aquatics Centre where designers used them to create stunning wave-like patterns on the roof, contributing to the centre’s distinctive aesthetic.

Silicone extrusions in the Eden Project’s biomes showcase their role in creating innovative and sustainable architectural designs. In both examples, silicone extrusions improve the design aesthetic and enhance functionality by improving energy efficiency and weather resistance.

Silicone extrusions offer architects and designers the opportunity to create innovative architectural features while maintaining the practicalities of longevity and durability. As weather-resistant materials, designers are increasingly using them to create complex façade systems. They offer both a modern aesthetic and a practical, sustainable solution. Durability and minimum maintenance make silicone extrusions a smart choice in architecture and design.

At Viking Extrusions, our team of silicone engineers has extensive experience working on many major construction projects around the world. Here are a few of the notable civil engineering projects we have been involved in over the years:

In home design, silicone extrusions have uses that go beyond their structural roles in windows and doors. They can contribute to the spatial design, comfort and safety of residential buildings. For instance, the construction industry uses them to provide insulation, dampproofing and soundproofing. Silicone extrusions can create unique design features, such as flexible LED lighting strips, and even create decorative elements that add colour, texture or shape to the home.

A unique residential application is the creation of modern, state-of-the-art bathrooms where silicone profiles are crucial in creating seamless and waterproof shower cubicles. They also enhance home aesthetics and safety by ensuring different floor levels transition smoothly, reducing the risk of tripping or falling. These examples demonstrate how silicone extrusions can contribute to enhancing the convenience, security and benefits of contemporary homes.

In residential buildings, designers can use silicone extrusions in intricate ways to improve the overall living experience of the occupants. For instance, by creating seamless connections between floors in the home and reducing tripping hazards, silicone extrusions have shown their worth. The damp-proofing and soundproofing applications of this material have also been pivotal in enhancing the comfort of modern homes.

In the commercial construction industry, the application of silicone extrusions is just as prevalent. The industry uses them in numerous ways, such as sealing gaskets for curtain walls and roofs, dampening noise or implementing heating, ventilation and air conditioning systems.

A notable application is in the glazing industry, where silicone extrusions are crucial components for installing large glass windows in commercial buildings, enhancing the aesthetics of the building and contributing to energy efficiency and safety by reducing air and water infiltration.

Viking Extrusions, established in 1983, is at the forefront of silicone extrusion technology. We specialise in creating custom silicone profiles, tubes, cords and 3D-printed silicone mould prototypes that cater to various design and architectural needs. Viking Extrusions can assist architects, designers and builders in their projects by turning ideas into reality with their innovative silicone extrusion solutions.

Whether you’re embarking on a large commercial project or a bespoke residential design, Viking Extrusions has the products and services to meet your needs. Our team of experts is on hand to guide you through the process, from conceptualisation to completion.

Silicone extrusions have unique applications in architecture, home design and commercial construction. Their versatility, durability and malleability make them beneficial for creating innovative and sustainable designs. They improve aesthetics, enhance functionality, add comfort and ensure safety in residential and commercial buildings. As we move towards a future that values sustainability, creativity and functionality, partnering with Viking Extrusions, a company that provides quality silicone extrusion solutions, becomes even more essential. Contact the team to see how we can help.

Silicone extrusions are the unsung heroes of the manufacturing industry. These flexible, resilient and heat-resistant components effectively enhance the functionality and lifespan of countless items we use daily. With their low thermal conductivity, silicone extrusions provide additional safety to everyday items by lowering the risk of overheating and accidental fires. You’ll find examples of extrusion products throughout almost every industry.

Whether through your morning cup of coffee or the car you drive, silicone extrusions are present behind the scenes, revolutionising the way these products operate. Viking Extrusions, a leading name in the industry, has played a significant role in this revolution. You can delve into 10 surprising ways silicone extrusions are reshaping the landscape of everyday products and discover some extrusion examples to help you shape your needs.

Silicone extrusions are a driving force in the automotive industry, offering incredible flexibility, durability and heat resistance. Manufacturers often use these extrusions to produce essential car parts, such as seals, tubing and gaskets. These components ensure the safety and longevity of vehicles, contributing to smoother rides and less frequent part replacements. Companies that utilise silicone extrusions can also pass value on to their customers.

Silicone extrusions have significantly impacted the medical industry. These components have dramatically enhanced the production of medical devices, as they are easily sterilised and biocompatible. Catheters and implants are just two examples of the products that now utilise silicone extrusions, making medical treatments safer and more effective.

In the food and beverage industry, silicone extrusions have become an integral part of various equipment. Their heat-resistant properties make them perfect for items such as extruded seals for ovens and baking mats. These applications can apply to businesses and individual customers. This revolution has resulted in safer, long-lasting kitchen tools and equipment.

In electronics, silicone extrusions shine with their thermal resistance and insulating ability. These components, common in wiring systems and keyboard buttons, have rendered electronic devices more durable and reliable. Their electric and heat resistance makes electronics safer and improves their overall longevity. Silicone extrusions can also minimise the heating effects of RAM-intensive programs when they run. The adaptability of silicone extrusions makes them a cornerstone in this ever-evolving industry.

Silicone extrusions have made significant strides in the construction and home improvement sectors. They are common in weather stripping and sealants, as their durability, weather resistance and cost-effectiveness make them a popular choice for constructors and homeowners alike. These rubber silicone products are economical and create added value for the customer.

Silicone extrusions benefit the fitness and sports industries considerably. Manufacturers have upgraded wearables and other fitness equipment with these components for better sweat resistance and comfort, enhancing users’ workout experiences. Extrusion examples are evident throughout this thriving industry.

Silicone extrusions are revolutionising the clothing and textile industry. Whether through waterproofing items or creating long-lasting, heat-resistant fabrics and safety gear, these exceptional materials have elevated the quality and durability of our clothing. Fabrics and other textiles can incorporate silicone without minimising the overall aesthetic appeal of the final product.

Ever wondered about the sleek design of your toothbrush or your razor’s comfortable grip? Silicone extrusions are the answer, with their unique potential to shape and mould personal care products. You can explore silicone extrusions to meet your manufacturing needs. Their hygienic and flexible nature makes them a perfect fit for this industry.

Silicone extrusions are leaving a colourful mark on children’s toy manufacturing. Their non-toxic and durable characteristics allow for the creation of safe, colourful and durable toys that children can enjoy for years. You can mould these toys into many shapes and sizes to fit even the smallest hands.

The aerospace industry relies heavily on silicone extrusions. Their unparalleled heat resistance and durability help in the production of various aerospace materials, ensuring safer and more efficient space travel. Silicone extrusions provide the necessary thermal resistance and mould into any size or shape, making these components easier to work with than traditional materials. Bespoke silicone rubber profiles are available in an extensive range of designs and sizes to suit your individual needs.

Throughout years of service, Viking Extrusions has catered to numerous national and international clients. Viking Extrusions has led the industry in silicone extrusion applications thanks to its years of industry experience and commitment to quality and innovation. Our clientele ranges from small businesses to massive corporations, and it is our honour to work with each customer.

You can find silicone extrusions everywhere. If you need a specific part, our team can help you explore your silicone extrusion options. At Viking Extrusions, we have over 30 years of experience delivering bespoke silicone products to different global markets.

Our dedicated team can show you how custom silicone extrusions might fit your needs. We strive to provide you with high-quality products that offer value to your customers and adaptive solutions to your manufacturing challenges. Get in touch with us now.

Silicone, a versatile and biocompatible material, has revolutionised many industries. However, its most profound impact has been in the realm of medical technology. With its unrivalled properties, silicone has enabled breakthroughs in medical treatments and improved patient outcomes. Viking Extrusions has been at the forefront of this innovation as a leading player in silicone extrusion technology.

Silicone holds several unique properties that make it an ideal choice for medical applications. Its biocompatibility ensures minimal tissue reaction when in direct contact with the human body. This makes it a safe option for use in implants, prosthetics and tubing.

Additionally, silicone is durable and able to withstand extreme temperatures, radiation and moisture, making it resilient and dependable in the challenging environment of healthcare. This durability helps to ensure the patient’s comfort and minimises the need to frequently replace equipment that might require surgical implantation.

Two other critical properties of silicone are its flexibility and translucency. The former allows it to form into intricate shapes without losing its strength and resilience. The latter aids visual monitoring in applications such as tubing. Silicone rubber tubing is used extensively by medical professionals during procedures and is one of Viking Extrusions’ essential products.

The use of silicone extrusions in medical applications is vast and ever-evolving. Our team is always ready to work with you to design, produce and meet your specifications. Some of silicone’s innovative uses include:

Silicone extrusions play a critical role in surgical instruments and devices, such as surgical tweezers and advanced endoscopes. Silicone is a non-reactive, durable and sterilisable material that manufacturers can fashion into precise, intricate shapes. These tailored shapes can make it easier for medical professionals to grasp and use the tools when performing precise medical procedures.

One everyday use is in medical tubing. This includes feeding tubes, catheters, IV lines and endotracheal tubes, which facilitate a variety of medical procedures and patient care needs. Our team can collaborate with you to tailor the design to meet your requirements for the tubing’s length and circumference.

Silicone extrusions enable prosthetics and orthotics to provide a comfortable, body-friendly interface that can conform to a patient’s unique physical structure while standing up to the wear and tear of daily use. The flexibility of silicone extrusions allows these parts to move more freely to meet the needs of the person wearing them. Professionals must tailor each prosthetic and orthotic for a specific person’s use, and silicone extrusions can make the process easy and more adaptable.

Implants and other internal medical devices are another area where silicone extrusions have made a significant impact. Silicone’s ability to maintain its structural integrity and biocompatibility despite exposure to the body’s internal environment makes it an excellent material for pacemakers, cochlear implants and artificial joints. The unique properties of silicone extrusions help to minimise the reaction of human tissue to its presence. Our team takes pride in offering only high-quality products for use in the medical industry.

Silicone extrusions are shaping the future of the medical industry, providing innovative solutions for diverse healthcare applications. Its resilience, durability, biocompatibility and flexibility allow silicone extrusions to meet and exceed the stringent demands of this critical sector.

Silicone’s unique and adaptable properties, combined with our technological expertise at Viking Extrusions, mean we can provide you with a solution tailored to your exact specifications.

As a leader in silicone extrusion technology with over 30 years of experience, Viking Extrusions holds a proven track record for delivering high-quality, customised silicone solutions for medical applications and pharmaceutical manufacturing. Our rigorous testing protocols and adherence to international standards demonstrate our commitment to quality and safety.

We work closely with our clients to develop custom solutions that meet the specific requirements of their medical applications. Be it a unique shape, size, hardness or colour, we can provide a silicone solution that fits your needs perfectly.

Extrusions play an integral role in shaping the industrial world. From automobile components and plastic tubes to food packaging and aluminium window frames, silicone extrusions are virtually indispensable. But what exactly is an extrusion?

Simply put, extruding is a process that pushes material through a die of a desired shape to create objects of a fixed, cross-sectional profile. Although various industries use them, silicone extrusion types and their uses often remain under the radar. At Viking Extrusions, we aim to shed light on the diversity and versatility of silicone extrusions.

Let’s explore the methods for extrusion and the materials that they use, along with the pros and cons of each method. That way, you can determine the right extrusion for your business.

Whether you’re a seasoned player in the industry or a newcomer seeking to understand the mechanics of extrusion, this comprehensive guide will equip you with the knowledge you need to make an informed decision.

Let’s look at what the extrusion process entails, the various methods of extruding materials, and how the different methods compare to one another.

The extrusion process involves forcing a material through a die (an opening set to produce a specific cross-sectional profile). This process uses high pressure and temperature to accomplish it.

As the material emerges on the other side of the die, it takes on a new form, reflecting the shape of the die. Depending on the method and the material, the extruded product can have unique characteristics that are suitable for various applications.

Several methods can extrude materials. The most common methods are hot extrusion, cold extrusion, warm extrusion, and dual extrusion.

Each extrusion method has its advantages and drawbacks. For example, hot extrusion allows for a higher rate of production and reduces the need for finishing processes. However, it can be more energy-consuming.

Cold extrusion, on the other hand, enhances the strength and hardness of the material, but it may be unsuitable for materials with low pliability. Weighing these factors will help guide your selection of the right extrusion method for your desired outcome.

There are many different types of extrusion, and each has unique qualities and applications. Two of the most common types of extrusion are silicone and aluminium.

At Viking Extrusions, we specialise in silicone extrusions that cater to a broad range of sectors, from automotive to food and drink. Silicone, as a material, is highly versatile, capable of withstanding varying temperatures, and resistant to ultraviolet light and ozone degradation. You can visit our silicone rubber profiles product page to learn more.

Among the common types of extrusion, aluminium stands out due to its lightweight nature, corrosion resistance, and thermal conductivity. Structural applications often use it in the automotive, construction, and electronics industries.

Aside from silicone and aluminium, you can also extrude other materials, such as steel, copper, and plastic. Each material has unique applications and advantages.

Selecting the right material for extrusion plays a significant role in the outcome of the process. The nature of the material can influence the method of extrusion, the temperature required, as well as the complexity of the final product’s shape.

Materials suitable for extrusion usually possess properties, such as high ductility and low melting points. Metals such as aluminium and copper, plastics such as high-density polyethylene and polyvinyl chloride and rubbers such as silicone meet these criteria.

Some materials may even require specific extrusion methods, such as brittle materials or those with low heat resistance. Cold extrusion will better suit these material types.

Understanding the properties of each material and how it interacts with the extrusion process can help you optimise your production processes and create high-quality extruded products.

If you’re unsure about what material is best for your specific application, that’s fine. Our experts at Viking Extrusions have extensive knowledge of the extrusion process, and we’ll help you pick the right material to reach your desired outcome.

Realising the full potential of extrusions requires a full understanding of silicone rubber and the pros and cons of each method of extrusion. In a nutshell, silicone extrusions are highly flexible, resistant to extreme temperatures, and excellent at providing electrical insulation. However, they might not be the top option for applications that require lots of strength.

In these cases, it is better to use aluminium extrusions. Many businesses prefer aluminium for its strength-to-weight ratio, corrosion resistance, and thermal efficiency.

Aluminium may not work effectively, however, in conditions that require high electrical conductivity. Similarly, other extrusion types have their own unique sets of advantages and disadvantages.

Silicone extrusions can serve as the top option for a variety of businesses, particularly in the healthcare, automotive, and food and drink industries. That’s because silicone extrusions are incredibly flexible, durable, and resistant to varying temperatures. Whether your business needs seals, gaskets, or tubing, silicone extrusions might be the ideal option for you.

Selecting the right extrusion boils down to understanding your business needs, the specific application, and the characteristics of different extrusion materials. It’s crucial to consider which factors, such as durability, flexibility, and resistance to temperatures and chemicals, are most important for your application to work properly.

Knowing the different types and methods of extrusions, their advantages and disadvantages and the benefits of silicone extrusions are fundamental to making an informed decision for your business needs. Our experts at Viking Extrusions are here to help you determine which silicone extrusion is right for your unique business.

Silicone extrusions are a game-changing material with a plethora of benefits. Their exceptional temperature resistance, water-repellent nature, and electrical insulation abilities make them a go-to option for various industries. While we often associate silicone with the automotive, aerospace, and medical sectors, it’s worth mentioning that it’s making its mark in several unexpected places. So, let’s explore five industries that rely on the versatility of silicone extrusions, and you will be surprised by what you learn.

Silicone, a synthetic material known for its uber-flexibility and resilience, is popular across many industries. Boasting temperature resistance, durability, water resistance, and electrical insulation ability, it is one of the most popular materials across industries for a reason.

One of the most notable properties of silicone is its extraordinary temperature resistance. It can withstand both extremely high and low temperatures without losing its integrity or changing its physical properties. This makes it an ideal material for applications in industries that operate across a broad temperature spectrum.

Silicone is famous in certain industries for its exceptional durability. It can weather harsh conditions and resist wear and tear, which ensures that it lasts for years without degrading. Silicone also exhibits excellent resistance to UV light, ozone, and radiation.

Aside from temperature resistance and durability, silicone also has excellent electrical insulation capabilities and water repellency. These properties make it suitable for applications in areas where electrical currents or moisture pose challenges. Discover six benefits of silicone in rubber production.

It’s clear to see why silicone is a popular and effective material across a variety of applications. Let’s look at five industries that surprisingly use silicone extrusions:

It may be surprising to discover that the use of silicone extrusions in beauty industries is quite common. For example, these industries may use silicone to form part of makeup applicators or incorporate it into the structure of beauty devices. Silicone’s hypoallergenic properties and skin-soft feel make it the perfect product to use.

Using silicone extrusions in agriculture is also quite popular. Their durability and resistance to harsh weather conditions make them perfect for greenhouse window seals, irrigation equipment, and livestock tagging devices. Our inflatable seals and silicone sponge sheets could be just what your agricultural business needs.

Additionally, silicone’s chemical stability makes it immune to detrimental effects from fertilisers and pesticides. It can mould into various forms, such as tubing or sheets, making it an adaptable solution for numerous agricultural needs. Its excellent insulation properties are also crucial for protecting equipment from temperature fluctuations, ensuring reliable performance.

In the food industry, silicone extrusions make food preparation and storage safer and more efficient. They have a function in the manufacturing of baking mats, seals for food containers, and even conveyor belts for food production lines. Silicone makes the products easy to clean and resistant to bacteria.

Silicone extrusions are also in cooking utensils and bakeware due to their non-stick properties. That means that you can easily remove food from pans and moulds without breaking them or leaving behind any residue. Silicone provides excellent heat resistance, which ensures safety during food handling and preparation.

On the machinery side, silicone seals and gaskets commonly feature in food processing equipment due to their ability to maintain structural integrity under extreme temperature variations.

Silicone extrusions also play a key role in the construction industry. The material’s excellent thermal insulation, soundproofing capabilities, and durability make it ideal for items such as windows, doors, and cladding seals.

Moreover, silicone extrusions are invaluable in the construction of green buildings. By helping to boost energy efficiency, silicone plays a significant role in the creation of economically and environmentally sustainable structures. The material is resistant to degradation by environmental factors, such as UV light, extreme temperatures, and even chemical exposure, making it ideal for outdoor applications in construction projects.

Silicone extrusions make a significant impact on the electrical industry. Their excellent insulating properties and resistance to extreme temperatures make them perfect for use in a variety of electrical applications, including where the voltage is high and insulation is crucial for safety purposes. Power transmission and distribution applications also use silicone extrusions, which provide critical performance enhancements.

Another important application of silicone extrusions in the electrical industry is in the manufacturing of keypads for electronic devices. Silicone’s flexibility, durability, and ability to retain its form even after frequent usage make it an ideal choice for this application.

They also commonly form part of LED lighting systems due to their high transparency and ability to withstand high temperatures.

Viking Extrusions offers a wide variety of silicone extrusions to meet the unique demands of each industry. By choosing us, you can benefit from years of expertise in producing high-quality, durable silicone extrusions that can withstand even the toughest conditions. Businesses worldwide have trusted our company to provide the best silicone extrusions for their applications for over 30 years, and we’re committed to helping yours too.

It’s astonishing to discover how many industries rely on silicone extrusions. They are crucial for beauty, construction, food-safe products, and energy efficiency. This underlines the amazing versatility of silicone as a material. If you want to learn more about how silicone extrusions could benefit your business, don’t hesitate to explore our product range.

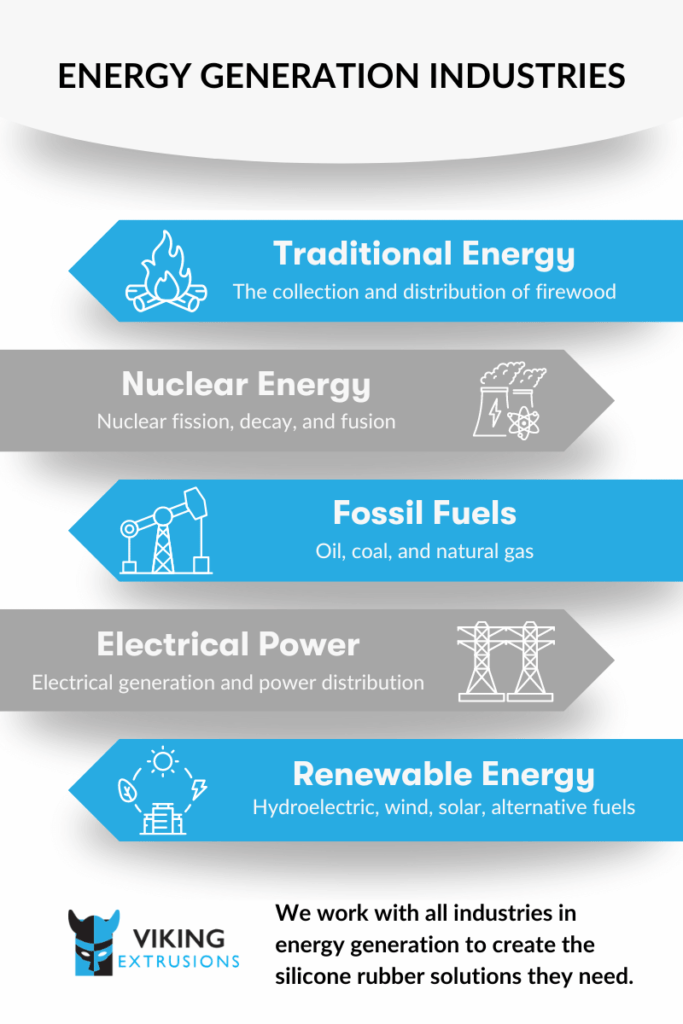

Silicone rubber is recognised as one of the most versatile materials, which also makes it one of the most popular. A range of industries use it to improve their processes and increase the lifespan of manufactured products. Its many positive qualities make it ideal for use in the energy generation industry.

Energy generation is a huge sector, encompassing a range of industries. Any organisation involved in the production and sale of energy comes under the umbrella of energy generation, which means that it includes the following:

Silicone rubber is suited to many different environments, making it ideal for use by the energy industry. It is versatile and durable, capable of withstanding the harshest conditions without compromise, and the variety of shapes it can take means that the energy industry uses it in different ways.

The solar industry has a strong focus on longevity, making silicone rubber an ideal product. It has proven especially useful in the creation of solar panel membranes. Silicone rubber sheets can be manufactured to different specifications, thicknesses, sizes, and to specialist grades if required.

The long lifespan of silicone, as well as its ability to flex, elongate, and resistance to tearing, provide the elasticity needed for solar panels. Using silicone rubber sheets, solar panel membranes can withstand the pressure used to bind solar cells together.

Rubber tubing is suited for any purpose, environment, or circumstance. Available in a variety of sizes with different specialist grades available, it is no wonder that the wind power industry utilises rubber tubing for hoses.

Our high-quality silicone has a high tensile strength, meaning that it will not split, helping to extend the life of your turbine and reduce costly downtime. Depending on your needs, we can create silicone hoses for wind turbines from 0.5 mm inside diameter up to 100 mm outside diameter.

The demand for natural resources that are extracted by oil and gas companies is increasing. With rigs across the world from cold Siberia to the hot Middle East, the fossil fuel industries need the right materials to withstand not only the vast temperature ranges but also the pressure that the material will be exposed to.

Rubber seals are ideal for this. Silicone seals are capable of withstanding great amounts of pressure without cracking or tearing, and the extreme temperature ranges make them perfect for use in certain machinery on oil and gas rigs.

The world is changing, and while we move towards clean energy production, the demand for nuclear power is still present. It is important for nuclear power organisations to use the right materials to extend the life of their operations and prevent potential hazards.

One of the most popular silicone products we produce for nuclear businesses is the rubber gasket. Silicone is perfect for gaskets, creating the tight seal required to repel materials. With extreme resistance to temperatures, UV and ozone properties, and chemical resistance, we create numerous nuclear gaskets.

Silicone rubber is widely used in different industries, especially in energy generation. Not only is it extremely versatile as a material, but it also is longer lasting than many other options and more durable.

Is silicone eco-friendly? It is considered to be a better option than plastic alternatives, as it enables businesses to act more sustainably. Manufacturing silicone doesn’t require mining, and while it is not biodegradable, it can be recycled. This makes it one of the best choices for businesses.

Are you an organisation in energy generation looking for the perfect solution? We can help. Contact the Viking Extrusions team to find out more.

The tech industry is always developing. Every day we learn about the latest tech trends and how technology can transform our lives for the better. At Viking Extrusions, we understand how important it is to have the most durable materials available to enhance the hottest technologies. Here’s how silicone rubber could be used within the tech industry.

The global economic climate means that many organisations are facing an energy crisis, rising inflation, and the threat of war. Despite these factors, Statista reports that the prospects of the tech industry for 2023 are mostly positive.

The continued growth and development means that new products and services are emerging. Silicone technology can make a huge difference, as it is an extremely durable material with extremely diverse applications. The tech industry encompasses numerous sectors including:

We cannot escape technology. Consumer electronics and handheld devices are so popular that mobile phones now outnumber people in the world. This is a worrying statistic, and one that will only grow.

The rise in technology has led to a demand for high-quality materials. We want our products to last for a long time, making durable materials essential. Silicone rubber is one of the most popular materials for a reason and boasts many benefits. The main benefits relating to technology are:

Heat resistance – Silicone rubber can withstand temperatures as low as -70°c and as high as 305°c. Given the amount of heat electronics and technology can generate, this makes silicone rubber the ideal material.

High tensile strength – Silicone rubber is much more resistant to fatigue and abrasions, helping the material to withstand some of the conditions that it endures within technology. From moving parts in computer hardware to forming a protective surface in communications, silicone rubber is a useful substance.

We’ve written everything you need to know about silicone rubber, where you can discover more advantages, how it is made, and the different products available.

Compact tech is becoming increasingly popular, and the tech industry faces the challenge of miniaturising devices and making electronic products more flexible.

Silicone is extremely flexible and durable, meaning that it can withstand the movement that flexible electronics demand. The material is reliable and allows great innovation, especially for wearable sensors, foldable smartphones, and flexible medical devices.

Wearable technology has revolutionised the way we interact with electronics, and silicone extrusions have become an integral part of achieving this innovative future.

The biocompatibility of silicone, combined with its hypoallergenic properties, makes it perfect for wearable devices. Fitness trackers, smart watches, and healthcare monitors require all of these properties as well as durability and flexibility.

The Internet of Things (IoT) has changed the way that devices communicate and interact with one another. Silicone has been a key part of this shift.

Silicone is durable and protective, ensuring that devices such as sensors and electronic components within IoT devices are resistant to different environmental factors. They are also insulating, making them vital to smart home devices, industrial sensors, and monitoring devices.

Telecommunications has advanced greatly within the last decade, with the demands for high-speed data transmission leading to improved innovations. Silicone extrusions have become an integral part of this.

The durability and reliability of silicone makes it perfect for fibre optic cables, connectors, and network equipment. It insulates the fibre optic cables from harsh environments and is resistant to different temperatures, ensuring that the cables can function effectively.

Specialist grades of silicone mean that tech innovators can continue to push boundaries and develop new technologies. Silicone is extremely versatile and can offer a range of durability, depending on the project. As the tech industry continues to evolve, silicone’s future promises groundbreaking applications that will revolutionise the way that we think not only about electronics, communication, and software development but also about other industries.

Want to see how silicone could help you create the technological solution of your dreams? Contact our team. We’re here to help.

© Viking Extrusions. All Rights Reserved.

Designed by Damteq.